PHYSICAL PROPERTIES

The physical properties of rubber effect compound selection.

Elastomers such as silicones have inherent physical properties, but these properties can be enhanced through compounding.

During compound selection it is important to understand a rubber’s physical properties and to know how each property is measured, so the select rubber materials can meet all your application requirement we will do our best to advise you in your choices of rubber compounds.

These are the physical properties of rubber.

The following sections provide a high-level look at each physical property.

Hardness: Elastomers have an inherent hardness because of their chemical structure. This hardness can be modified, and the processed hardness then measured in terms of durometer (duro) on a Shore scale. For soft to medium-hard rubber, Shore A is used. At 40 duro, solid rubber profiles have the consistency of pencil erasers. At 90 duro, they’re hard like hockey pucks. Which hardness do you need?

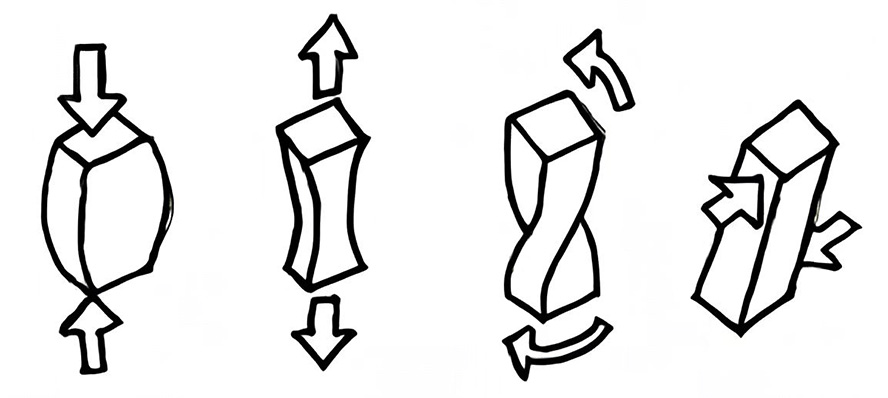

Tensile strength: (TS) is the amount of force that’s required to pull a rubber specimen apart until it breaks. Known also as ultimate tensile strength (UTS), TS is measured in either pounds per square inch (psi) or megapascals according to ASTM D412. For technical buyers and part designers, tensile strength matters because it represents a rubber’s point of failure caused by stretching.

Tensile modulus: (TM) sounds similar to tensile strength, but these two properties are not the same. TM is the force or stress that’s required to produce an elongation percentage or strain in a rubber sample. In general, harder rubber has a higher tensile modulus. Such rubber is more resilient, but also more resistant to extrusion, a process for manufacturing stock materials used in custom fabrication.

Elongation: is the percentage increase (strain) in the original length of a rubber sample where a tensile force (stress) is applied. Some elastomers stretch more than others. For example, natural rubber (NR) may stretch up to 700% before reaching its ultimate elongation, the moment the NR breaks. By contrast, fluor elastomers may rupture at 300% elongation. How much do you need your rubber parts to stretch?

Resilience or rebound refers to a rubber’s ability to regain its original shape and size after a temporary deformation, such as contact with a metal surface. Resilience is especially important in dynamic seals, components that create a barrier between moving and stationary surfaces. If your application requires weatherstripping between a door and a door frame, the compound’s resilience is important to consider.

Compression set: is the amount by which an elastomer fails to return to its original thickness after a compressive load is released. When a rubber seal is compressed repeatedly over time, progressive stress relaxation occurs. In terms of the seal’s life, stress relaxation is like dying. Compression set is like death itself – the end result of a steady decline in sealing force. How long do you need your seal to last?

Tear resistance: describes an elastomer’s resistance to the growth of a nick or cut when tension is applied. Also known as tear strength, this physical property is measured in either pound force per inch (lbf/in) or kilonewtons per meter (kN/m). If you need edge trim that will contact rough metal edges or sharp objects, consider tear resistance during compound selection.

Abrasion resistance: describes a rubber’s resistance to being worn away from rubbing or scraping. In industrial applications, abrasion-resistant rubber is used with conveyor belts that move coal and in pumps that handle slurries. Material loss due to abrasion can be measured with various instruments according to tests such as ASTM D394.

Specific gravity: is the ratio of the weight of a material to the weight of an equal volume of water at a specified temperature. For chemists, it provides a way to identify compounds. For technical buyers and part designers, it’s important to know that rubber with a low specific gravity offers more square inches per pound of stock. Rubber with a higher specific gravity provides advantages in molding consistency.

Queries or need for assistance on optimal rubber parts?Call us if you prefer to talk to our employees in person. We will be delighted to help you.

View on Mobile

Copyright © 2022-2023 Codan Tech Qingdao 鲁ICP备15018330号

powered by WDL